The construction industry operates at a quickly-expanding pace, leaving safety managers with daily challenges as they supervise multiple locations. Problems seem to flare up everywhere, and they never feel fully in control.

Construction companies that adopt AI-driven oversight are strengthening safety controls even when teams are spread across different regions. Automated tools give site managers much greater visibility into risks and mobile access to check jobsite conditions from any location.

AI tools identify safety hazards as they arise and automatically produce the alerts and reports needed to inform the best response, allowing construction leaders to intervene before minor incidents snowball into major damage and losses.

Our article explains how AI-driven detection systems help safety managers identify early warning signals and act fast before problems escalate. We highlight how surveillance and analytics work together to build a stronger, more dynamic safety culture in multi-site environments.

The Need for Speed in Jobsite Safety

Accidents and injuries happen in seconds on construction projects. For instance:

- An inexperienced worker enters a high-risk area without permission and is hit by heavy machinery.

- A crew member not wearing a hard hat is fatally struck by a falling glass panel.

- Welding sparks and combustible materials quickly produce a large blaze.

Early intervention by safety personnel is critical to pull the inexperienced crew member from the restricted zone and ensure proper protective gear is worn at all times.

But proactive oversight is impossible if monitoring depends on physical patrols and periodic checks. Even if you only manage one jobsite, you can't be everywhere at once. If you have to travel between two or more construction sites, the window between inspections widens, and competing priorities distract your focus and effectiveness.

Without visible, active oversight, hazards like PPE failures, noise violations, and exposure to toxins go undetected and unreported. Unsafe behaviors and conditions become normalized very easily.

This is why construction firms are now leveraging AI-driven project management solutions that deliver real-time monitoring and alerts, allowing safety managers to stay on top of multiple risks and jobsites from a single point.

How AI Analytics Software Work to Enable Early Risk Detection

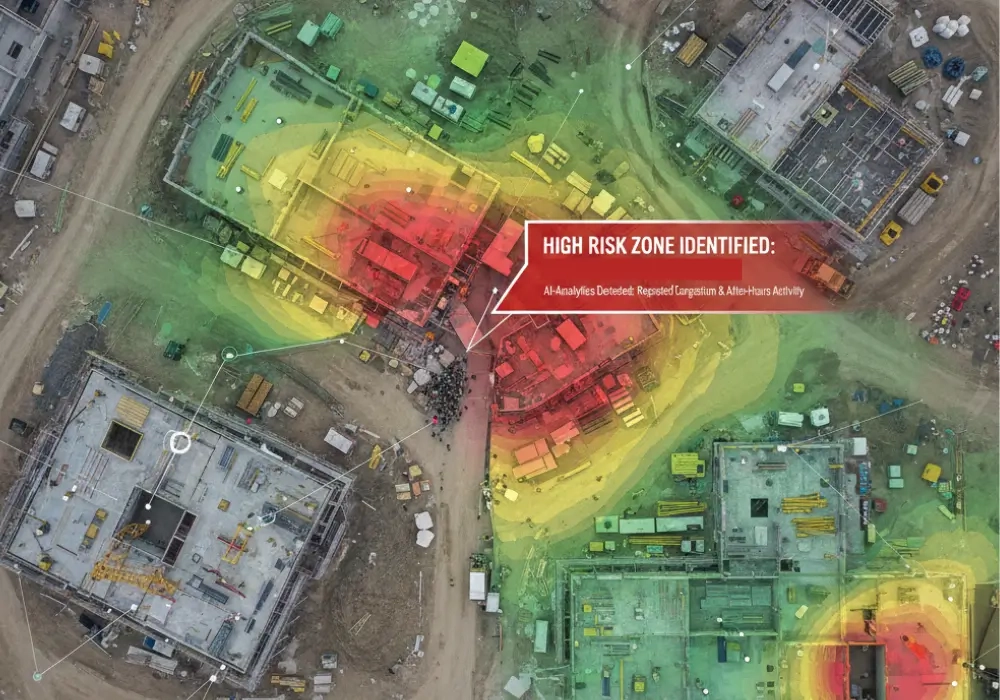

AI analytics tools use machine learning algorithms to identify hazards faster and more consistently than human monitoring.

AI systems are trained on thousands of video examples to understand the characteristics and patterns of the risks they monitor. They analyze video or IoT-based sensor feeds continuously to track and account for:

- Critical environmental data (air pollutants, sound levels, weather risks)

- PPE adherence

- Perimeter breaches and intrusions

- Unsafe behaviors

- Fire dangers

- Other potential safety hazards

When a risk is detected, they immediately send an alert to the responsible manager/team so action can be taken in real-time.

AI systems using computer vision filter out false positives, raising alarms only for clear and present dangers. For example, AI in construction security can distinguish between a genuine trespasser and false indicators like passing vehicles, wildlife, or flapping sheets.

Operating continuously across shifts and different lighting conditions, these systems give safety and project managers complete real-time visibility into all hazards across multiple construction sites. For compliance and audit purposes, they maintain an evidence-backed record of the event for as long as required.

With 87% of companies making AI a top priority in their business plans, it's unsurprising that the construction industry is investing heavily in AI analytics to manage project safety more effectively.

Read more: How AI-Video Analytics for PPE, Fire, and Smoke Detection Ensures Jobsite Safety

How AI Analytics Expands Safety Across Multiple Jobsites

Artificial intelligence and smart tools expand visibility across all your jobsites. Three core components that make this possible are:

- Analytics Software (as discussed)

- Intelligent Surveillance

- Centralized Reporting

Intelligent Surveillance

High-definition PTZ cameras and advanced sensors capture project data, which is organized and presented to you by AI algorithms. Cameras/sensors are mounted on smart surveillance systems, including:

- Solar Surveillance Trailers: These rapidly deployable units enable wide-area monitoring of remote construction sites and workspaces without permanent infrastructure.

- Pole Cameras: Equipped with infrared (IR) night vision, easy-to-install pole cameras deliver targeted surveillance for entrances, material storage zones, high-risk work areas, and perimeters.

- Temporary and semi-permanent camera installations: Installed based on your safety and resource allocation needs.

These versatile setups provide near-360° visibility across even the most complex project management environments, reducing the need for frequent in-person safety checks.

Read more: Why Smart Surveillance Systems Are the Future of Business Security

Centralized Reporting

Scattered data and switching between apps waste 10% of each workweek and make it hard for safety leaders to see the full picture.

With AI-driven systems, all surveillance feeds, alerts, and sensor data flow into a centralized interface, like our secure, cloud platform Stellifii. This unified dashboard consolidates safety, security, and compliance information into one user-friendly view.

The complexity of multiple feeds is transformed into clear insights that you can access from any connected device, whether you're on the road or at a remote site.

And the best thing is that reporting is generated without manual involvement. Your foreman doesn't need to complete spreadsheets, and your team doesn't have to decipher conflicting testimonies to compile a fall report.

Stellifii presents the complete, accurate information you need to make the best decisions at the push of a button. This capability hugely simplifies safety and compliance efforts. It also saves you money as you no longer have the cost and administration of running multiple systems.

The scalable cloud platform is end-to-end AES-256 encrypted to protect sensitive worker, client, and project data. It is also NDAA‑compliant, meaning that the system/infrastructure is authorized for use on federal contracts.

Read more: The Rise of Smart Construction Jobsites: How Tech Is Transforming the Industry

6 Core AI Safety Systems for Construction Projects

To enhance construction safety and security, we offer cutting-edge AI-powered surveillance and monitoring solutions, such as Smart Detection Systems (PPE, intrusion, fire), environmental monitoring, and jobsite security systems.

Personal Protective Equipment (PPE) monitoring scan jobsite zones continuously for required safety equipment, including:

- Hard hats

- High-visibility vests

- Goggles

- Hearing protection

- Safety boots

- Respiratory masks

When a worker enters a designated zone without proper equipment, the system automatically captures a timestamped snapshot and sends real-time alerts to project managers. The incident, including the corrective action, is logged on Stellifii, creating a record of enforcement.

With OSHA fines reaching up to $165,541 per violation, automated PPE monitoring reduces financial and legal exposure while protecting workers more effectively than inconsistent spot checks.

The US construction industry loses $1 billion+ annually to theft, vandalism, and unauthorized access. Intrusion detection with AI analytics monitors site perimeters and restricted zones continuously, guarding against:

- Border breaches

- Unauthorized access to off-limit sectors

- Trespassing and vandalism

- Metal, materials, tools, and equipment theft attempts

Our fully-managed and easily deployable surveillance network (on trailers, temporary cameras, or other mobile monitoring setups) uses AI to detect suspicious behavior and trigger immediate warnings.

Advanced analytics distinguish real threats from potential false triggers, such as passing wildlife, weather, debris, and blowing tarps, and retain logs and video evidence for reporting and investigations.

Read more: The Benefits of Integrating Your Security and Communications Systems

Extreme weather can play havoc with carefully planned construction processes. To stay ahead of nature's challenges, weather monitoring stations track meteorological conditions continuously, including:

- Extreme temperatures

- Winds (speed and directions)

- Humidity

- Rainfall

- Storm indicators

AI monitoring stations protect the crew and site from imminent danger (high heat, heavy rains, winds) by activating work stoppages when necessary and help prevent Department of Labor citations and OSHA penalties.

Accurate, up-to-date weather insights enable construction managers to reschedule activities around weather events to keep project timelines on track.

Besides safeguarding the crew from hearing damage, analytics-backed noise control proves compliance with regulations and ordinances. Integrating directly into Stellifii, noise monitoring devices continuously monitor jobsite sound levels across:

- 30-130 Decibels

- 20Hz to 12.5kHz frequency

The system generates instant alerts and records for noise violations and potential hazards, like spikes from machinery or blasting.

The National COSH reports that thousands of US workers die every year from long-term exposure to hazardous substances. To mitigate risks and harm from airborne hazards, air quality sensors measure:

- Dust and PM1, PM2.5, PM10 particulate matter

- Volatile organic compounds (VOCs)

- Chemical fumes

- Carbon dioxide (CO₂)

- Carbon monoxide (CO)

IoT sensors capture thousands of data points every hour, storing up to 180,000 time-stamped records for trend analysis and compliance reporting. They trigger immediate alerts if pollutant thresholds or safety levels are breached, allowing you to pause, adjust operations, and/or eliminate hazards to restore acceptable air quality.

Read more: Air Quality Data Management: Turning Sensor Data Into Actionable Insights for Jobsites

- License Plate Recognition(LPR) and Access Control

License Plate Recognition is an automated system that tracks and logs all vehicles entering and exiting the jobsite(s). With LPR, you get better:

- Access control

- Theft prevention

- Vehicle accountability

- Vehicle safety on site

With every entry and exit logged, LPR supports investigations and provides audit trails for compliance.

3 Other Applications of AI in Construction Environments

AI-powered tools have become a vital component of modern jobsite security and fire prevention.

-

Live Video Monitoring: Our security service integrates live monitoring, where trained specialists respond within seconds to suspicious or criminal behavior detected on AI-powered cameras.

-

Smoke and Fire Detection: Advanced smoke detection uses high-definition cameras and AI to scan jobsites 24/7 for flickering light and heat signatures that indicate early-stage smoke or flames. When a fire threatens your operations, the system flags it instantly, generating a timestamped image and surveillance footage so responders understand the challenge.

-

Other services: A Time Lapse Video service offers engaging short-form videos of the build's progress for the client and key stakeholders, which can also be used to motivate construction teams.

Read more:

The Benefits of AI Analytics in Construction

Comparing AI safety tools to less digitally transformed approaches demonstrates how impactful this technology can be in keeping crews safe and projects running smoothly.

| Project Outcomes/Benefits | AI Analytics | Existing Systems (Manual/Low-Digital) |

| Risk Detection | Real-time detection with automated alerts enables fast intervention before incidents become significant problems. | Delayed identification, depending on scheduled inspections and manual reporting, means you're always a step behind. |

| Audit Readiness | Continuous, time-stamped data capture produces excellent audit trails and compliance reporting. | Fragmented records and manual logs slow audits and weaken compliance defenses. |

| Predictive Risk Management | Predictive analytics anticipate hazards, enabling prevention before accidents happen. | A reactive approach can only confront risks after they've possibly already escalated. |

| Data Analysis/Data Quality | Advanced analytics uncover hidden trends, recurring safety failures, and high-risk areas and behaviors. | Basic reporting with less visibility into hazards and little actionable insight. Data quality control is variable. |

| Project Efficiency | Automation streamlines workflows and boosts overall productivity. Safety officers can prioritize higher-value tasks rather than routine inspections and paperwork. | Manual processes are inefficient and often unproductive, requiring more headcount, yet delivering slower responses. |

| Consistency Across Multiple Sites | Centralized AI monitoring standardizes oversight and enforcement across all projects. Bringing everyone onto the same page creates a stronger, consistent safety culture. | Monitoring varies by supervisor and frequency of site visits. Crew members get confused and frustrated by inconsistent messaging/enforcement. |

Read more: Top Strategies for Ensuring Jobsite Safety

Achieve Preventive Safety with AI Insights

By integrating AI insights, safety officers gain a powerful advantage in protecting crews and jobsites.

Intelligent monitoring and detection deliver immediate alerts and remote access to the latest safety data, enabling prompt corrective actions.

Automated reporting ensures audit requests from regulators or insurers can be answered in minutes with defensible, timestamped documentation.

To strengthen your safety program and better protect your workforce and company's assets, contact us for more details about trusted AI solutions made for construction safety.